Concrete Crack and Joint Caulking and Repair in Washington & Northern Idaho

Concrete naturally deteriorates over time. Weather changes, soil movement, heavy loads, and freeze-thaw cycles all contribute to cracking, joint separation, and surface wear. Left untreated, these issues can worsen quickly — allowing water intrusion, creating trip hazards, weakening slabs, and accelerating structural failure.

At Slabjack Geotechnical, we provide professional concrete crack repair services and joint caulking to protect your concrete from long-term damage. Serving Washington and Northern Idaho, we use advanced repair materials and proven installation techniques to restore performance, improve safety, and extend service life for both indoor and outdoor concrete surfaces.

Whether you are a homeowner, property manager, or facility operator, our team delivers reliable concrete crack repair solutions designed for the unique demands of residential, commercial, municipal, and industrial environments.

What Is Concrete Crack and Joint Caulking — and Why It Matters

Concrete crack repair and joint caulking are essential maintenance practices that strengthen slabs and prevent further deterioration. When cracks appear, water enters and expands the problem — eroding the subgrade, washing out soil, and causing additional cracking and settlement. Joint failure allows movement and separation between slabs, which undermines stability and surface alignment.

Professional concrete crack repair and expansion joint caulking address these concerns by:

- Sealing gaps to block moisture

- Preventing erosion and soil washout

- Reducing freeze-thaw damage

- Maintaining alignment and slab integrity

Just as important as the repair itself are the materials and techniques used. Slabjack applies commercial-grade epoxy, silicone, and polyurea products engineered for flexibility, adhesion, and long-term performance. \Proper installation ensures the sealant shields the slab, resists movement, and protects against harsh Northwest climate conditions.

Concrete Crack and Joint Caulking for Residential, Commercial & Industrial Properties

Every property has unique environmental and operational challenges. Slabjack Geotechnical provides tailored concrete crack sealing services across a diverse range of surfaces and industries.

Residential Concrete

Including: driveways, patios, sidewalks, walkways, and porches

Common issues: expansion gaps opening, moisture infiltration, aesthetic wear

Homeowners benefit from improved curb appeal, safer walking areas, and longer-lasting concrete without costly replacement.

Commercial Concrete

Including: storefronts, parking lots, curbs, entry paths, loading areas

Challenges: higher foot traffic, weather exposure, ADA compliance

Businesses rely on crack repair to reduce liability risks, maintain appearance, and support heavy loads.

Industrial Concrete

Including: warehouse floors, machine areas, forklift paths, fabrication facilities

Challenges: vibration, chemical exposure, constant load pressure

Industrial slab durability is critical — crack and joint sealing prevents slab shift, water intrusion, and workplace hazards.

Our team has worked with properties of every scale, giving us the experience needed to diagnose issues accurately and execute solutions efficiently.

How We Use the Geopolymer Injection Method

Many cracks form because the slab has begun to settle or the supporting soil has shifted. Simply sealing cracks without addressing underlying voids or instability often leads to recurring issues.

Slabjack Geotechnical utilizes a refined geopolymer injection method — an advanced alternative to traditional mudjacking or concrete replacement. This technique stabilizes the soil and lifts the slab prior to sealing.

How Geopolymer Injection Works

- A lightweight expanding polymer is injected beneath the slab through small holes.

- The material fills voids, supporting the slab from below.

- Controlled expansion lifts and stabilizes the concrete evenly.

- Once cured, the polymer remains durable, waterproof, and inert.

Why It Outperforms Mudjacking

- Cleaner and less invasive

- No large equipment or slurry mess

- Faster cure time with minimal downtime

- Permanent stabilization without added weight

Stabilizing the slab first ensures that crack and joint repairs last — preventing further separation and creating a stronger foundation for caulking materials.

Our Step-By-Step Crack Repair and Joint Caulking Process

Our systematic approach ensures lasting performance, durability, and a clean finish.

- Inspection & Assessment: We identify active cracks, joint failures, and underlying causes.

- Surface Preparation & Debris Removal: Dust, crumbling material, and contaminants are removed to ensure sealant adhesion.

- Slab Stabilization (if needed): Geopolymer injection is performed to lift or support the slab.

- Routing & Cleaning Cracks and Joints: Precision tools prepare cracks for optimal sealant depth and structure.

- Material Selection: We choose epoxy, silicone, or polyurea based on environment, movement, and load.

- Injection & Caulking Application: Cracks and joints are filled and shaped for a smooth, clean appearance.

- Finishing and Curing: Edges are tooled for uniformity; curing ensures long-term protection.

- Final Quality Check: We verify integrity, finish, and functionality before project completion.

Exterior Crack Repair Using Epoxy Injection

Epoxy injection is designed to bond concrete surfaces and restore structural integrity.

- Two-part epoxy is injected into routed cracks.

- Silica sand may be added for strength and surface texture.

- Weather-resistant seal ideal for driveways, patios, and exposed slabs.

- Once cured, the repair can be left as-is or coated.

This method provides a tough, permanent seal — ideal where appearance and durability are both priorities.

Interior Crack Repair Using Polyurea Injection

Polyurea is the preferred option for indoor crack treatment due to its flexibility and rapid cure time.

- Fast-curing, low-odor, and highly flexible

- Penetrates hairline cracks deeply

- Bonds well even under movement and vibration

- Can be left exposed or coated with epoxy flooring

Polyurea’s properties make it the best choice for warehouses, garages, basements, and industrial flooring subject to mechanical stress or temperature changes.

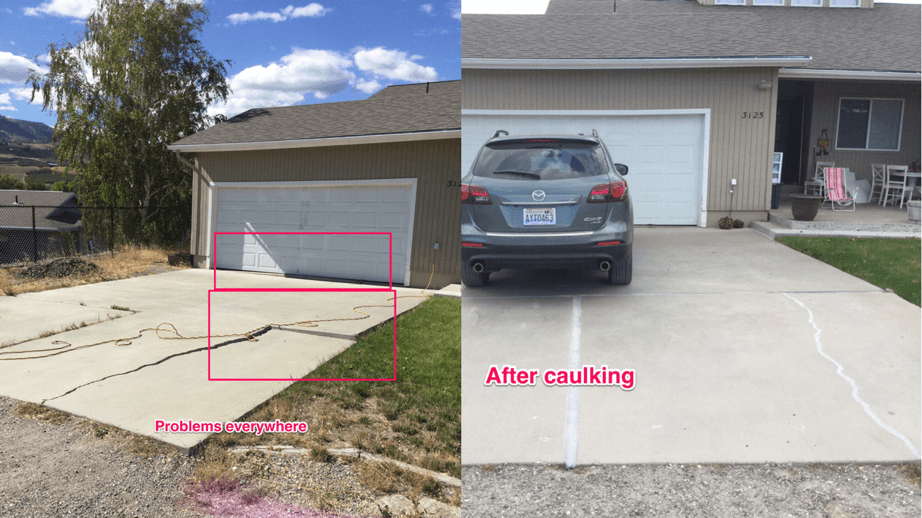

Before and After: A Noticeable Improvement

Professional crack and joint sealing restores concrete surfaces visually and functionally. After repair:

- Surfaces appear cleaner and more uniform

- Joints are protected against moisture and soil erosion

- Slip and trip hazards are minimized

- Cracks stop spreading and remain sealed

Service Area: Concrete Crack Repair Near Me

Looking for dependable concrete crack repair near me? Slabjack Geotechnical proudly serves customers across Washington and Northern Idaho. Our main office in East Wenatchee allows us to provide fast, localized service to:

- Spokane

- Wenatchee

- Tri-Cities

- Coeur d’Alene

- Surrounding Northwest communities

We are a trusted local provider with deep experience in Northwestern climates and soil conditions — uniquely suited to prevent deterioration caused by moisture, freeze cycles, and shifting ground.

Protect Your Concrete With Proven Crack Repair Solutions

Proper crack repair and joint caulking safeguard your concrete against long-term damage and costly replacement. With structural stabilization, commercial-grade sealants, and professional installation, Slabjack Geotechnical ensures results that hold up against weather, weight, and time.

For reliable concrete crack repair services backed by expertise and the region’s most trusted techniques — work with the specialists committed to performance and precision.

Contact us today to request a free inspection, quote, or to schedule your concrete crack repair project.

Frequently Asked Questions

What happens if I ignore cracked concrete?

Cracks allow moisture to enter, causing erosion, soil shift, and slab movement, which lead to more costly repairs over time.

Can I repair concrete cracks myself with hardware store caulking?

DIY caulks often fail quickly because they don’t bond deeply or withstand freeze-thaw expansion; professional materials and preparation ensure long-term results.

Why do concrete cracks reopen after being sealed?

If the slab is unstable or the soil below has settled, cracks can return — which is why stabilization and geopolymer injection may be required before sealing.

How soon can repaired concrete be walked or driven on?

Most crack and joint sealing cures within hours, though timing depends on whether epoxy or polyurea is used and the environmental conditions.

Will the repair blend in with the existing concrete?

While repairs improve appearance significantly, color variation can occur; finishing techniques and silica sand filler help achieve a more uniform look.